Differential Scanning Calorimetry (DSC)

In the previous post, we discussed different types of process safety tools in short. So now as promised let us go into details of each tool separately.

Let us begin with the very first screening tool of Process Safety: DSC.

DIFFERENTIAL SCANNING CALORIMETRY (#dsc )

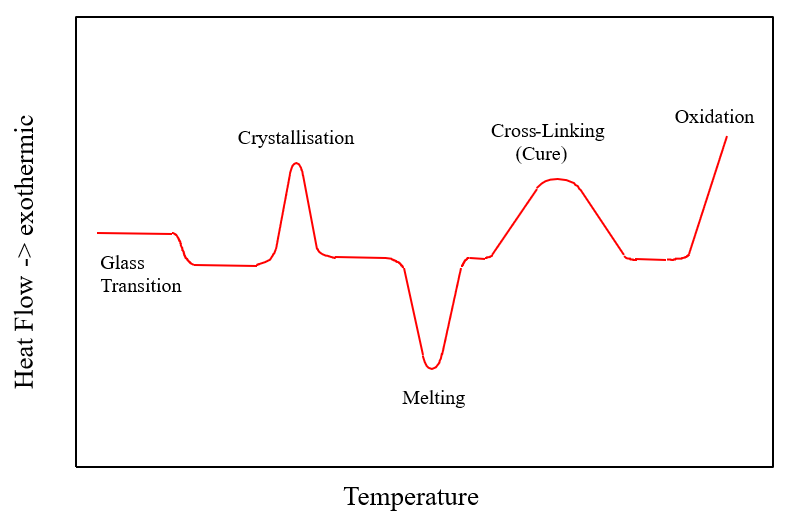

It is a thermal analysis of a sample in which the difference in the heat required to increase the temperature of a sample and reference are measured.

DSC is a preliminary screening tool in Process Hazard analysis.

There are three basic types of DSC instruments:

1. Power Compensation DSC

2. Heat-flux DSC

3. Modulated DSC

Application:

1. Study phase transition

2. #melting point

3. Melting #Enthalpy

4. Glass Transition

5. #Endotherm onset temp

6. Endothermic Energy

7. #Exotherm Onset temp

8. Exothermic Energy

9. #ThermalStability

10. Analysis of materials

11. #HeatCapacity

Advantages

1. Wide range of temperatures

2. Any material in any form can be tested

3. Sample quantity is very small (<10 mg)

4. Shorter Analysis time

Disadvantages

1. Interpretation of results is quite difficult

2. Result may vary even though the same sample is reanalyzed

3. Accuracy of the results is comparatively less than #ARC (Accelerated Rate Calorimetry)

In certain cases, we can use #DTA also for the replacement of DSC. The major differences between these techniques are mentioned in the attached image.

Note- If the characteristic temperatures (Endotherm/exotherm) onset near the operating temp of your process then the sample must be analyzed on ARC also for better accuracy.

Let us see the details of ARC in the next post.

Associate Principal Scientist, Eurofins Advinus Biopharma Services India Pvt.Ltd., Bengaluru (Ex. Wavelength, Emcure, Ajanta, Harman Finochem and Jubilant)

1yDSC Analysis

- şirketinde Mühendis

1yThanks for sharing. I have an observation (I have tried many times): Glass loses Na2O as it turns into a crystal. When Na2O is added to the crystal, it turns into glass again. Sometimes only heating and cooling may not be sufficient in glass-crystal transformation.

Associate Scientist, Oral Care I&S

1ySushil Chavan Sir great/good initiative. Keep posting such informative blogs/posts about other techniques/concepts too. Keep spreading knowledge. I would like share one question was asked to me by manager of instruments selling MNC company during interview. He asked me applications of DSC, as usual I just enlisted some of from chemical and safety related applications. He said there are others applications too for checking the purify and stability of chocolate and food products. He said they are selling more number of DSC and TGA machines to chocolate and food industries than any other chemical and pharma industries. I was amazed how could chocolate industry afford such high price machine. But when I did some literature about the price of chocolate in India I was shocked. Its price starts from 1500-2500/ kg. This price is way more than that of some of the chemicals which are said to be costlier. Thanks

.Consultant and author of two books

1yWriting in own language ( no copy paste ) is the best way to learn. What you write is your asset.